Tool room

Discover our departments

Learn more about our individual departments. Any information is available here.

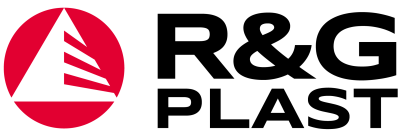

Tool room

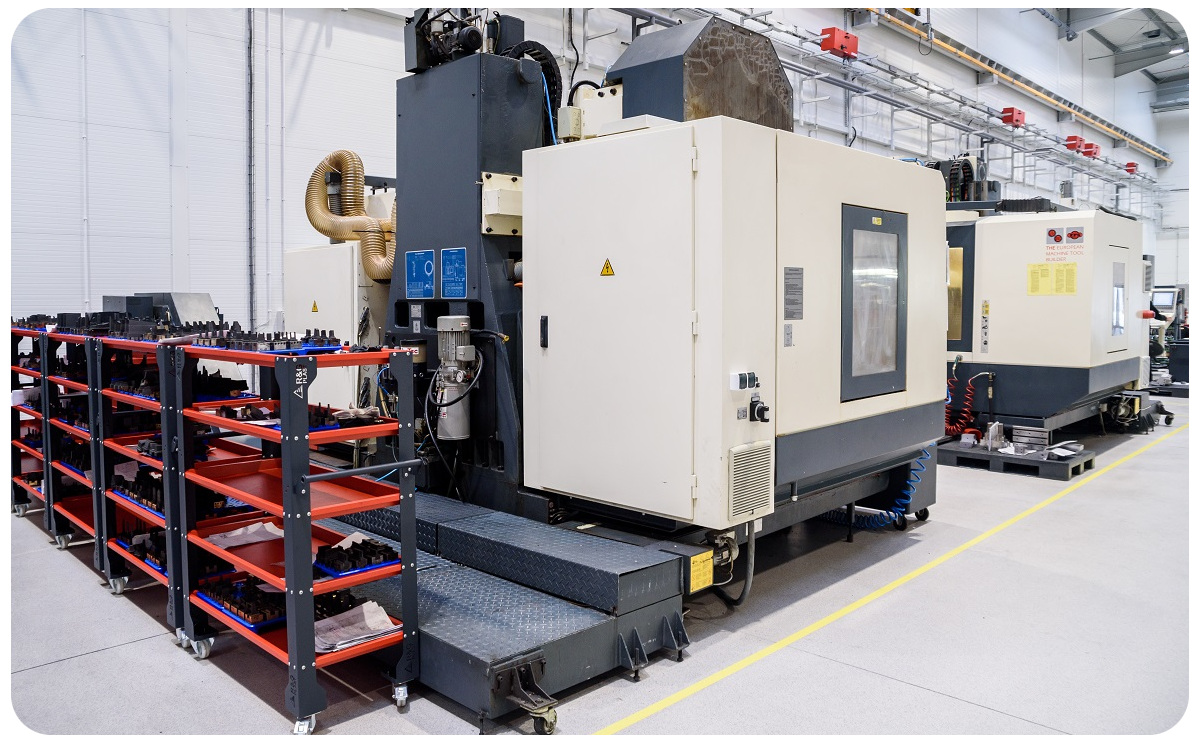

We are experts in manufacturing injection moulds intended for the processing of plastics with maximum overall dimensions of 2,500 × 1,500 mm and weighing up to 15 t. We have more than 30 years of experience in manufacturing injection moulds. With our current capabilities, we can make approximately 120 injection moulds per year and, at the same time, handle more than 300 moulds operating at R&G Plast. The Tool Department has had a significant impact on the successes achieved by R&G Plast and our constant production development.

What makes us unique

We are a unique injection mould manufacturer because to manufacture injection moulds, we can use our own professional injection moulding plant to verify the correctness of the moulds, which allows us to save time for unnecessary mould transfers, and owing to the possibility of making test injections, we are able to guarantee the highest quality of workmanship and manufacturing of injection moulds.

The high quality of the moulds that we manufacture is confirmed by numerous Polish and EU customers. Guided by your needs, we can offer perfect solutions for both low-volume prototype series and series production. Depending on the requirements, we make prototype or series injection moulds.

We are fully involved in any order we perform. Due to our professionalism, reliability, and timely delivery of orders, we have gained the trust of numerous customers. That is why we are perceived as a valuable partner in the sector of services related to plastic component processing. We employ a team of qualified construction engineers, developers, CNC machine operators, and tool fitters who have many years of experience in the field. With the competence of our construction engineers and powerful software, we can anticipate hazards resulting from complex geometries of moulded pieces and take actions to optimise the design. In this way, we are able to avoid many design-related issues as early as at the design engineering stage. At every mould preparation stage, we monitor the key processing parameters and the required processing time. All the above aspects contribute to the professional character and reliability of the tasks we execute.

The Tool Department manufactures single- and multi-component injection moulds for customers from the following industries:

- Houseware

- Automotive

- Cosmetics

- Electrical

- Construction

- Horticultural

- Medical